UltraPract®: Biogas Enzyme Generation 2.0

Goal: Increasing performance and economic viability of your biogas plant

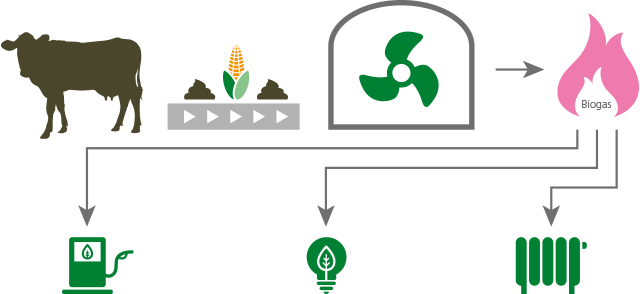

The current framework conditions for the operation of biogas plants enforce the reduction of costs and the maximization of efficiency and output. Low-cost substrates - in particular renewable resources, such as liquid manure and dung - are an alternative to the conventional energy crops. As a result, biogas plant operators are increasingly reducing the corn content in the substrate mix. However, alternative substrates present a challenge to biogas plant management and fermentation process biology. Technical adaptations for pre-treatment to increase substrate utilization require considerable investments and are energy-intensive during operation. This supports the application of effective enzyme additives for biotechnological optimization. Extensive lab studies and application trials in large-scale biogas operations provide clear evidence for the effectiveness of 2nd generation enzymes as a cheaper alternative.

Competence in the development of enzyme solutions for technical applications is the foundation of our business. With the innovative product series UltraPract, Biopract ABT opens up a new dimension for the efficient use of enzymes in the biogas sector. In particular when feeding considerable amounts of animal wastes, the highly effective UltraPract® P2 improves the biogas yield to an extent unimaginable until now.

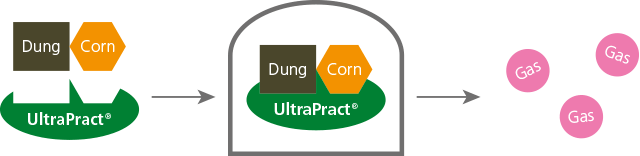

More dung, less corn - the success formula that you can profit from!

UltraPract® products optimize the biogas production process

The anaerobic microorganisms in a biogas plant utilize their own enzymes to degrade the substrate blend to methane and carbon dioxide in a multi-stage process. The first step of this process (hydrolysis) is often slow (rate limiting) because of insufficient enzyme activity. Therefore, suitable external enzyme products can be added to complement the present bacterial enzymes. This will accelerate the attack on the long-chain molecular structures of the plant fibers and thereby improve the entire degradation process.

Enzymes are highly effective biocatalysts. Since most enzymes have a very substrate-specific effect and their optimal efficacy is temperature and pH value dependent, the selection and combination of the right enzyme activities is crucial for the biogas process. Targeted enzymatic degradation of plant cell wall material and structural components in farm fertilizers, such as dung and slurry, offers considerable potential to improve biogas process efficiency. More dung and less corn means increased profitability.

The latest findings from the Biopract Labs confirm that enzymes of the 2nd generation complemented by the innovative enzymatic AC Factor not only accelerate the process, but also make previously unused substrate components available for further degradation in the fermenter. Energetically unused biomass is fed to the fermentation process by targeted enzymatic attack. Due to the increased degradation rate, the fermentation residue is measurably reduced.

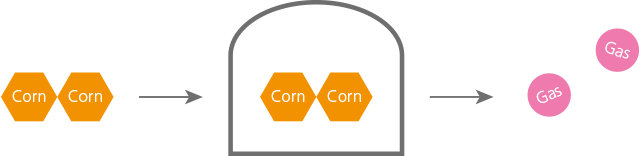

Without UltraPract®

With UltraPract®