UltraPract® P2

The biogas enzyme 2.0 with AC Factor boost

UltraPract® P2 was specially developed for application in biogas plants.

The result: Peak activity in the pH range 7.0 - 8.5 relevant for biogas plants and thus optimal efficacy. In addition UltraPract® P2 offers an extraordinary temperature tolerance > 60° C as well as uncompromising stability.

The enzyme combination complemented by the enzymatic acceleration factor AC ensures the superior efficacy of UltraPract® P2. The impressive results from practical application provide convincing evidence.

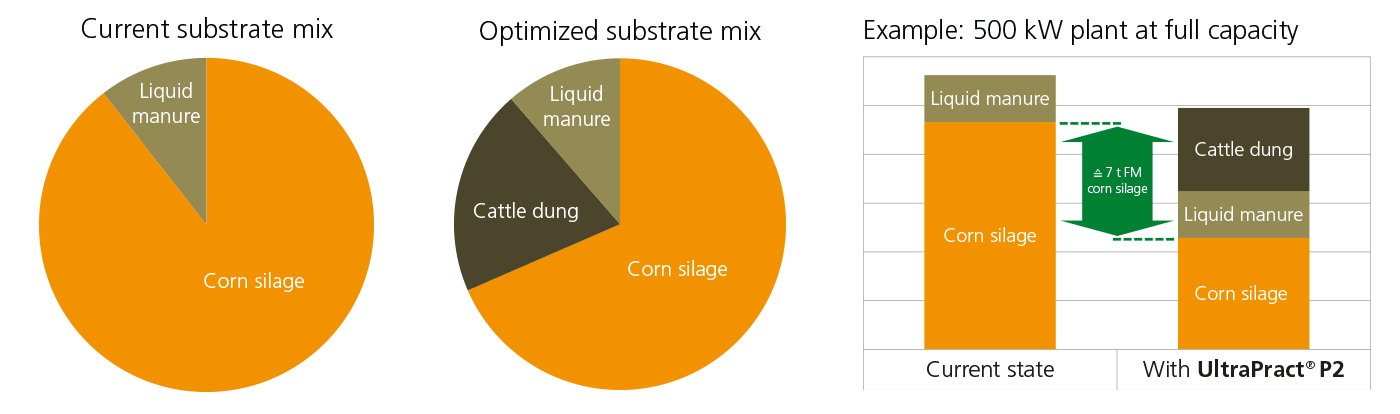

UltraPract® P2 provides an attractive option for biogas plant operators interested to increase the share of animal wastes (dung, liquid manure). Furthermore, when using substrates with a high proportion of fibers (e.g. straw, grass silage, weed silage), the addition has proven its particular effectiveness.

Take advantage of our service: We will work with you to find the best application for your biogas plant!

5 good reasons for the application of UltraPract® P2!

- Maximizes the speed of biogas formation.

- Increases substrate utilization, and thus the entire degradation to biogas.

- Facilitates increasing the proportion of animal wastes in the substrate mix - at constant plant output and stable operation.

- Optimizes the productivity, and thus the profitability of plant operation.

- Reduces the amount of fermentation residue.

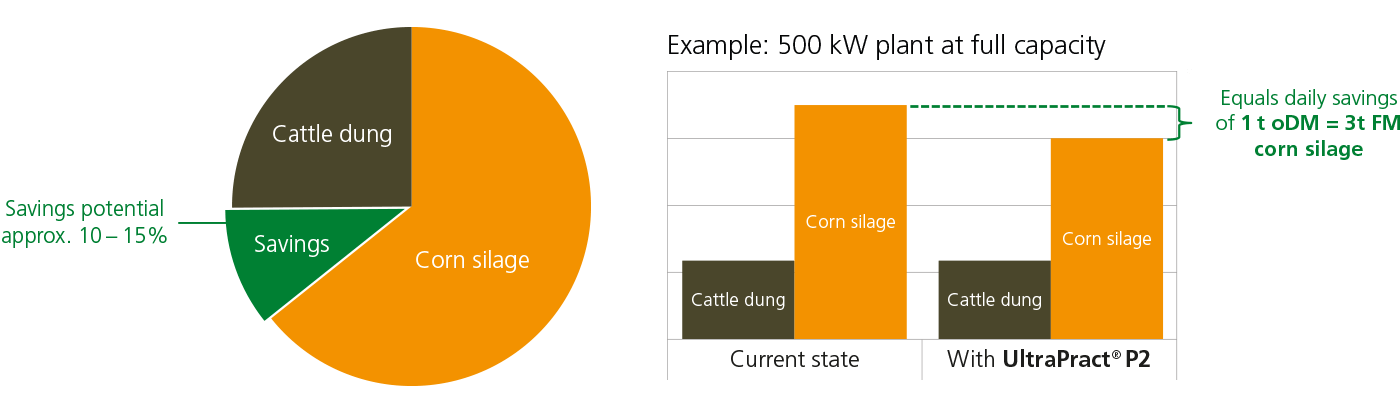

More dung, less corn!

Higher yield, less fermentation residue!

UltraPract® P2: Functionality and Effect

The highly effective UltraPract® P2 complemented by the enzymatic AC Factor introduces the next generation of biogas enzymes.

Developed in Biopract GmbH's labs, UltraPract® P2 is a liquid concentrate consisting of specially formulated enzymes. UltraPract® P2 increases and accelerates the utilization of co-substrates such as dung and slurry, as well as difficult to ferment fiber components. As a result it speeds up the fermentation process, increases the biogas yield and thus lifts the profitability of the operation.

Moreover, the improved substrate utilization leads to a substantial reduction of fermentation residue. In a 500kW plant a reduction of 600 -800 m3 a year can be achieved.

The Turbo for Higher Yields!

UltraPract® P2 enables the reduction of the substrate intake by 10-15% for plants, which already apply more than 25% of animal wastes (e.g. cattle dung), without sacrificing performance*.

Cost brake for expensive substrates!

Additionally, an increased share of animal wastes can result in considerable savings of expensive, energy crops (corn silage, grain) without a reduction in output. Biogas production is thus made possible with a much more cost-effective substrate mix*.

* Data based on oDM (organic dry matter) and FM (fresh matter)